As we navigate the electric vehicle revolution, the discourse is no longer just about range, speed, or style. It probes deeper into the sustainability narrative – how does it all come together, right from the assembly line to your driveway? In this article, we delve into the behind-the-scenes process of packaging and delivering these eco-friendly machines. Prepare to plunge into the world of EVs beyond just the drive – a journey where packaging and transportation also echo the sustainability ethos.

Emergence of Electric Vehicles

A brief sojourn back in time offers the perspective that the electric vehicle (EV) revolution isn’t as overnight as it seems. It’s an intriguing plot of human innovation, driven by Preston Tucker, Elon Musk, and the like, meshed into the core dynamics of power matrices and environmental sustainability.

Speed and smart engineering have always been salient in the auto industry. However, in the last decade, sustainability has become a compelling selling point as well. The rise of EVs has happened simultaneously with an increased global awareness regarding climate change. Quite abruptly, that became part of the mission for many auto manufacturers too, due to consumer demand and government pressures alike.

Initially, electric vehicles seemed the stuff of futuristic rendering, greenwashing our access to grounded spacecraft. Yet, here we are in the present day, where driving an EV is neither exclusively for the elite nor the environmental zealot. This is partly attributable to companies like Tesla which, while starting out premium, eventually branched out to produce user-friendly, accessible models. Many traditional automakers also hopped onboard, transitioning from internal combustion to electric drivetrains, thereby mainstreaming EVs.

However, the accelerated pace of EV production created an imposing challenge: handling the rise in production in the most eco-friendly way possible. Indeed, creating these machines in the first place requires a significant footprint if not managed appropriately. From extraction of lithium for batteries to energy-intensive processing and assembly, the risk of swapping one environmental concern for another is real.

Shaped by these pressures, the auto industry has responded by developing practices that go far beyond simply doing away with fossil fuels on the road. As a result, electric vehicles are entering a new phase – the era of sustainable packaging and delivery. Some pioneering firms are delivering EVs in a way that compliments their minimal environmental impact and addressing the carbon footprint from factory to driveway. This transformative approach aligns with the ethos of many EV drivers, prioritizing lifecycle impacts over just the charm of exclusively emission-free driving.

Sustainable Packaging Practices for EVs

We all love the thrill of peeling off that thin plastic film from the surfaces of our fresh, tech-laden electric vehicles. There’s a sense of satisfaction in its newness, a clean start. But did you ever consider what happens to all that glossy packaging once it’s served its purpose? That’s where sustainable packaging practices for EVs come into the picture.

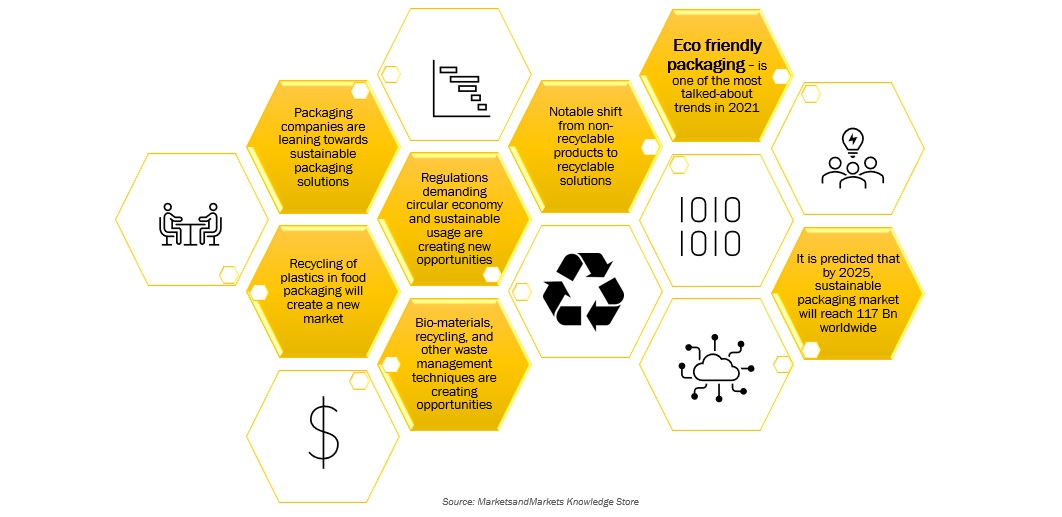

Due to the increasing demand for EVs, the production of packaging waste is also on the rise, which spells bad news for the planet. However, automakers, true to their environmental objectives, are actively employing sustainable packing practices to lessen this impact.

One common approach is through the use of returnable packaging. For example, protective coverings can be used to transport EV parts and then sent back to the manufacturer for reuse. It’s a great system that cuts down on waste and can save manufacturers money in the long run. But it’s not just about reuse. Design elements are also being optimized to reduce the overall packaging required. And for the material that is used, sustainability is key.

Consider the electric vehicle batteries. They’re heavy, they’re valuable and they need to be protected. Traditionally, this would mean packaging them in single-use plastic. But now, manufacturers are revolutionizing this concept through the use of pallets made from recycled plastic or other recyclable material, offering a sturdy solution that is also environmentally friendly.

What about the little things, you may ask – like the protective films that are applied to the interiors and exteriors of the vehicles during transportation? More and more manufacturers are opting for bio-degradable versions of these films, made from plant-based materials rather than plastic. On arrival, these films can be composted instead of ending up in the landfill.

Of course, there is a cost associated with this switch to sustainable packaging practices. It might mean having to source more expensive materials or invest in redesigning parts for optimal packing. But it’s a price manufacturers are willing to pay, as they recognize their responsibility to lead by example when it comes to environmental stewardship. And perhaps the rest of us could pick up a trick or two from this philosophy!

Lastly, it’s not only about the packaging materials but also the processes behind them. Many manufacturers are tapping into renewable energy sources, recycling as much waste as possible and continuously aiming to improve their supply chain’s efficiency. This ensures that the sustainable packaging practices are just as green as the vehicles they hold. The conclusion is clear: when it comes to EVs, sustainability truly goes beyond the drive.

The Delivery Process of EVs

Now, onto the presentation’s grand finale: the delivery process. In case anyone thought this was where the EV industry faltered in its commitment to consciously crafted sustainability, buckle up. If anything, EV brands have taken this part of the process as a chance to showcase just how much of a game changer they are when it comes to emissions and the environment.

Most automakers deliver EVs using the same process as any other vehicle – jacking them up onto giant, diesel-belching trucks before hauling them to their new homes. But others are following a different path that looks a lot like the future of vehicle delivery to the end consumer. It might not be as glamorous as the lustrous body of an EV or the whiz-bang tech under the hood, but when it comes to sustainable commerce, this last step is just as crucial.

One strategy being adopted by EV companies is to engage in local assembly or knock-down operations. This involves shipping the components of vehicles to assembly points closer to where these vehicles are to be sold – reducing long haul transportation and supporting locally sustainable jobs.

Imagine an electric vehicle showing up at your doorstep, straight from the factory, having generated zero tailpipe emissions along its journey. Now, that’s a reality. Yes, the vehicles are literally driving themselves off the factory floor and to their owners’ doorsteps, producing zero emissions along the way. This kind of precision and efficiency isn’t merely dazzling—it’s a logical and responsible use of autonomous capabilities.

Additionally, some companies are exploring options to reduce single trip loads, thus introducing multi-modal transportation. A combination of cargo ships, trains, and electric trucks, all done in a systematic, carefully planned manner to reduce the emissions normally generated in delivering vehicles to dealerships and clients.

By developing creative solutions and pursuing sustainable options at every turn, the EV industry confirms that it’s about more than just producing zero-emissions vehicles. It’s all part of an innovative dedication to sustainability that comes standard with every EV, right down to the way it’s delivered to your driveway. This is a silent revolution in the auto industry, slowly changing the load-and-go, throwaway culture of the past. With these revolutionary steps, the delivery process of EVs paints a future that’s bright for consumers, manufacturers, and the planet.

Case Studies: Sustainable Packaging and Delivery of EVs

While the broader story of EV sustainability typically zooms in on the cars themselves, the tale of their packaging and delivery is equally noteworthy. A few industry leaders spring to mind when considering the innovative work currently being done in the field.

Take Tesla, for instance. The electric vehicle giant has been famously committed to sustainability not just in the production of their cars but also their delivery process. Tesla carries out direct deliveries, significantly reducing the overall carbon footprint of their vehicles by bypassing the traditional dealership model. Their so-called ‘Tesla Direct’ program even delivers the car straight to the customer’s doorstep, minimizing any unnecessary transportation and packaging related emissions. This direct-to-consumer delivery model is expected to set a precedent in the auto industry, embodying the concept of sustainability beyond the drive.

On the packaging end of the spectrum, BMW is leading the charge. Recognizing that even electric cars can cause significant environmental harm in terms of packaging, BMW has committed to using reusable materials and minimizing waste where possible. The use of recycled or recyclable materials in their packaging starts a cycle of sustainability that continues throughout the life of their vehicles. Vehicles are shipped in containers made from environmentally responsible materials, like recycled plastic. Plus, these containers are designed to be flat-packed when not in use, saving considerable space during transportation and reducing the overall carbon footprint of delivery.

Nissan, another heavyweight in the electric vehicle sector, has taken a similar approach to packaging. The Japanese automaker has made a pledge to use solely sustainably sourced and recyclable materials in their packaging. This focus on renewables even extends to the crates in which vehicles are shipped to dealerships. Made from recycled materials, these crates can be disassembled and recycled once they’ve served their purpose.

Transitioning to an era of electric vehicles is not just about the vehicles themselves. It’s about changing every element of the traditional auto-industry paradigm. From the packaging materials to the delivery processes, the forward-thinking automakers are leading the industry in revolutionizing the way we think about cars, ensuring every aspect of the car’s life cycle is as sustainable as possible.

FAQs

What does sustainability mean in terms of EV packaging and delivery?

How important is sustainability in the delivery of EVs?

What are some approaches to sustainable EV packaging and delivery?

Conclusion

In conclusion, as electric vehicles are rapidly evolving, so too must the methods of their packaging and delivery. Manufacturers are challenged to limit carbon footprints, by implementing innovative, environmentally friendly packaging and transportation solutions. From biodegradable materials to reducing shipment spaces, this commitment to sustainability extends far beyond our driveways. It underpins our journey towards an emission-free world where electric vehicles aren’t just about a greener drive, but also a more sustainable life.